Flame-retardant PP is mainly used in black home appliances, because white home appliances have higher requirements for aesthetics, and the performance of flame-retardant PP in this aspect is still not ideal. Because flame-retardant PP has the advantages of easy processing and low price, PP materials are generally used to make some components that do not have high requirements for the beauty of the material, and have high requirements for heat resistance and flame retardancy, such as: TV housings, computers The wiring terminals, washing machine control panel seat, remote control housing, refrigerator evaporation dish, ventilation ducts, wall switches and other components with potential combustion hazards in the chassis.

In order to avoid fires, many countries now require that the materials used in electronic and electrical components in household appliances must be flame-retardant. Among flame-retardant PP materials, 63% require UL94 V-0, 23% require UL94 V-2, 12% are DIN4102 B1, and 1% are other flame-retardant grades. Flame-retardant PP materials can better meet the flame-retardant needs of home appliances while reducing production costs. The following describes the flame-retardant performance requirements of several types of flame-retardant PP materials used in home appliances.

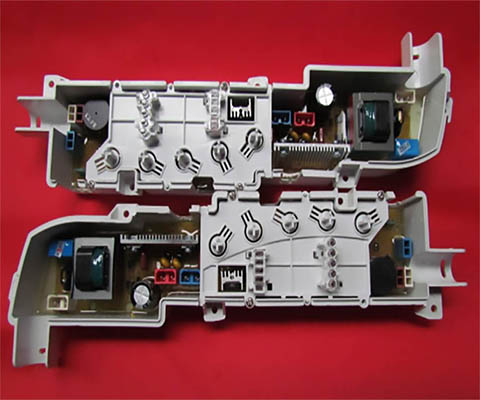

1. Washing machine tray housing

The washing machine tray housing mainly plays a role of fixing and protecting the circuit board of the washing machine. During the operation of the washing machine, some parts may generate sparks due to a short circuit. Therefore, in order to operate the circuit board more safely, many manufacturers have put forward flame-retardant modification requirements for the shell material of the motor panel.

Through flame-retardant modification, flame-retardant PP material can reach UL94 V-0 level, and can withstand 650℃ or even 750℃ glow wire without ignition.

2. Home appliance socket shell

Household appliance socket switches belong to the category of small household appliances, and the sockets of the household appliance sockets and the connecting terminals are made of flame-retardant materials. In order to enhance the price competitiveness of products, companies gradually began to use flame-retardant PP instead of flame-retardant ABS to make household socket housings.

For example, the socket shell has already been upgraded from the past ABS material to flame-retardant PP material, and the flame-retardant temperature has risen from 650°C to 750°C. The quality of the socket shell material determines the service life and safety of the socket. In terms of safety, flame-retardant PP material is currently the preferred material for the housing of home appliance sockets.

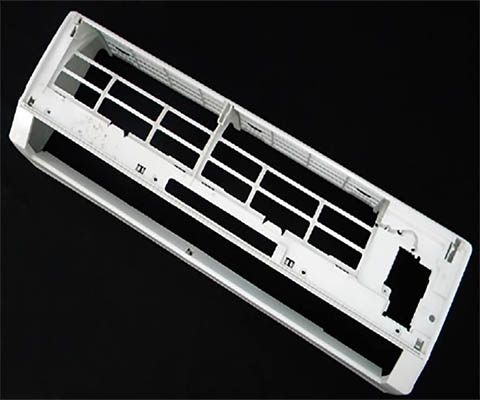

3. Air conditioner shell

For the housing of the indoor unit of the household air conditioner, the traditional material choice is generally HIPS or ABS, but in recent years, there has been a gradual emergence of aging-resistant PP material alternatives. With the continuous improvement of consumers' safety requirements for indoor household appliances, many air-conditioning companies have begun to use flame-retardant PP as the material of the indoor unit shell.

In addition to meeting the basic performance and flame-retardant performance requirements of the air conditioner shell, flame-retardant PP also has obvious advantages in anti-aging performance compared to materials such as flame-retardant ABS.

Copyright © POLYROCKS CHEMICAL CO., LTD. All Rights Reserved |

Sitemap

| Powered by

粤ICP备10040394号

粤ICP备10040394号

CONTACT US

QUICK ENQUIRE FORM

* Indicate Mandatory fields