PP is commonly referred to as polypropylene. It has the characteristics of high strength, high insulation, low water absorption, high forming temperature, low density and high crystallinity. Since PP has so many advantages, what should we pay attention to in the PP injection molding process to make better products?

PP injection molding processing needs to pay attention to the following aspects:

1. Treatment of PP raw materials

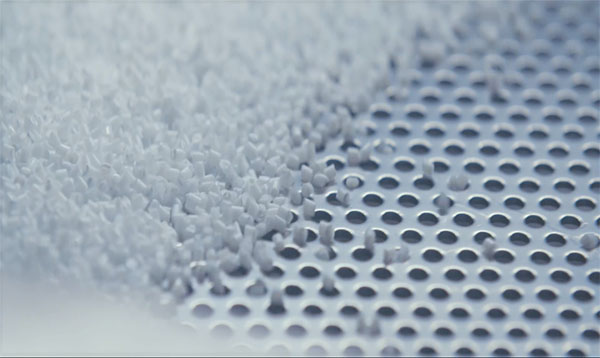

Pure PP is translucent or milky white particles, which can be dyed into various colors. PP generally uses color masterbatch for dyeing. Products used outdoors are generally filled with UV stabilizers and carbon black. The use ratio of recycled materials should not exceed 15%, otherwise it will cause strength drop and decomposition and discoloration. Generally, no special drying treatment is required before PP injection processing.

2. Selection of injection molding machine

There are no special requirements for the selection of injection molding machines. Due to the high crystallinity of PP, an injection molding machine with higher injection pressure and multi-stage control is required. The clamping force is generally determined at 3800t/㎡, and the injection volume is 20%-85%.

3. Mold and gate design

The mold temperature is 50-90°C (high mold temperature is used for higher size requirements). The core temperature is more than 5℃ lower than the cavity temperature, the runner diameter is 4-7mm, the needle gate length is 1-1.5mm, and the diameter can be as small as 0.7mm. The length of the edge gate is as short as possible, about 0.7mm, the depth is half the wall thickness, the width is twice the wall thickness, and the length of the melt flow in the cavity gradually increases.

The mold must have good venting. The vent hole is 0.025mm-0.038mm deep and 1.5mm thick. To avoid shrinkage marks, use large and round nozzles and circular runners, and the thickness of the ribs should be small ( Such as 50-60% of the wall thickness). The thickness of products made of homopolymer PP should not exceed 3mm, otherwise there will be bubbles (thick wall products can only use copolymer PP).

4. Melting temperature

The melting point of PP is 160-175°C, and the decomposition temperature is 350°C, but the temperature setting cannot exceed 275°C during injection processing. The temperature in the melting section is preferably 240°C.

5. Injection speed

In order to reduce internal stress and deformation, high-speed injection should be selected, but some grades of PP and molds are not suitable. If the patterned surface appears with light and dark stripes diffused by the gate, low-speed injection and higher mold temperature should be used.

6. Melt adhesive back pressure

5bar melt adhesive back pressure can be used, and the back pressure of the toner material can be adjusted appropriately.

7. Injection and pressure keeping

Use higher injection pressure (1500-1800bar) and holding pressure (about 80% of the injection pressure). It takes a longer time to switch to holding pressure at about 95% of the full stroke.

8. Post-processing of products

In order to prevent shrinkage and deformation caused by post-crystallization, products generally need to be soaked in hot water.

Copyright © POLYROCKS CHEMICAL CO., LTD. All Rights Reserved |

Sitemap

| Powered by

粤ICP备10040394号

粤ICP备10040394号

CONTACT US

QUICK ENQUIRE FORM

* Indicate Mandatory fields