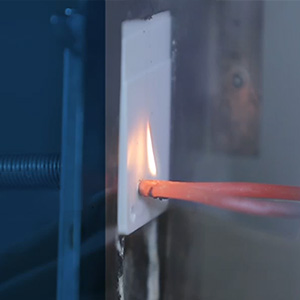

Flame retardant system: Using phosphorus and nitrogen as main flame retardant elements

Main application: Home appliance shell, coil bobbin, controller shell, electronic and electrical products, etc

Flammability rating: UL 94 V0

Glow Wire Grade: GWIT:775/3.0 and GWFI: 850/3.0

Features: Low density, low smoke, high flame retardant efficiency; low shrinkage, high modulus

PS:We can provide you with free samples for evaluation and test, please feel free to contact us

Product Introduction: The flammability of 5000B can reach UL94 V-0 (1.5mm and 3.0mm). 5000B has UL certificate and meets the requirements of RoHS, SVHC, PFOS&PFOA, 17P, and PAHs, etc. 5000B has the characteristics of low density, low smoke, high flame retardant efficiency; low shrinkage, high modulus, and less corrosion to the molds.

HFFR PP

Application: Home appliance shell, coil bobbin, controller shell, electronic and electrical products, etc.

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

UL94 V0

Flame retardant performance: Phosphorus and nitrogen as the flame retardant elements.

Temperature: GWIT:775/3.0mm and GWFI: 850/3.0mm

Characteristic: low density, low smoke and less corrosion to the molds

| Specification | Test Method | Unit | High modulus halogen-free flame retardant PP |

| Density | ASTM D792 | g/cm3 | 1.15 |

| Melt Flow Index (230℃/2.16kg) | ASTM D1238 | g/10min | 10 |

| Heat deflection temperature | ASTM D 648 | ℃ | 125 |

| Mold Shrinkage | ASTM D955-08 | % | 0.87 (vertical) |

| 0.87 (horizontal) | |||

| Tensile Strength | ASTM D638 | MPa | 20 |

| Elongation at Break | ASTM D638 | % | 50 |

| Flexural Strength | ASTM D790 | MPa | 30 |

| Flexural Modulus | ASTM D790 | MPa | 2300 |

| Izod Notched Impact Strength | ASTM D256 | J/m | 40 |

| Flammability | UL 94 | 1.5mm | V-0 |

| 3.0mm | V-0 |

Remark: The above laboratory test data are just for reference only; it's not a basis for quality assurance.

Plug

Socket

Coil bobbin

Coil bobbin

Speaker enclosure

Dear customers, no need to worry about your products colors, POLYROCKS has professional colour matching department, providing free colour matching service. Any colour requirements, kindly please contact us by email: sales@polyrocks.com.

POLYROCKS focus on provide prompt pre/after-sales service, we have professional injection molding engineers and technical service engineers to provide accurate information and timely service. Any questions or needs, you are welcome to contact us by email: sales@polyrocks.com.

Any purchasing questions, welcome to contact our customer service, helps will be provided by them.

Copyright © POLYROCKS CHEMICAL CO., LTD. All Rights Reserved |

Sitemap

| Powered by

粤ICP备10040394号

粤ICP备10040394号

CONTACT US

QUICK ENQUIRE FORM

* Indicate Mandatory fields