Product description: UV cross-linked low smoke halogen-free flame retardant PE

Main application: Color cable only (not available in black)

Flammability rating: Passed IEC60332 single cable vertical burning, C-type bunch burning test

Temperature class: 105℃

Features: Excellent mechanical properties, electrical properties,flame retardant performance and processing performance. Burning without halogen acid gas, very little releasing of toxicity and corrosion gas, and with little smoke.

PS:We can provide you with free samples for evaluation and test, please feel free to contact us

EP8400X105J-1 temperature resistance is 105℃, with excellent Mechanical properties, electrical properties, flame retardant performance and processing performance.

XLPE Granule

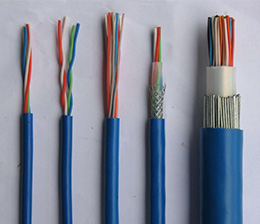

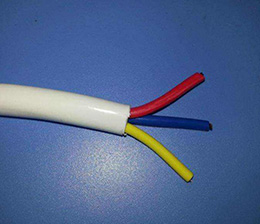

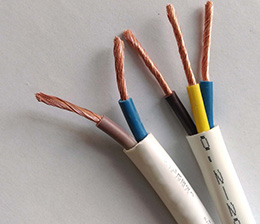

Indoor Colored Wire——XLPE Product

Wire & Cable

Application: Color cable only (not available in black)

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

XLPE

Flame retardant performance: Meet the requirements of IEC 60332 single cable vertical burning.

Temperature: 105°C

Characteristic: excellent Mechanical properties, electrical properties, flame retardant performance and processing performance.

| Properties | Test Standards | Units | UV XLPE (Low smoke HFFR ) | |

| Density | ASTM D-792 | g/cm3 | 1.49 | |

| Shore Hardness D | ASTM D 2240 | -- | 51 | |

| Tensile Strength | IEC 60811-1-1 | MPa | 11.5 | |

| Elongation | % | 185 | ||

| Aging 136℃×168h | Tensile strengthretention | IEC 60811-1-2 | MPa | 13.5 |

| Elongationretention | % | 169 | ||

| Thermal extension(200℃, 0.2MPa, 15min) | Elongation underloading | IEC 60811-2-1 | % | 55 |

| Permanent deformation aftercooling | % | 3 | ||

| -20℃Brittle temperature | IEC60811-1-4 | -- | Pass | |

Combustion performance

| Properties | Test Standards | Units | UV XLPE (Low smoke HFFR ) | |

| Oxygen index | ASTM D2863 | % | 34 | |

| Smoke density | Flaming | ASTM E-662 | — | 65 |

| Non-Flaming | — | 225 | ||

| pH | IEC 60754-2 | — | 5.2 | |

| Electrical conductivity | μS/mm | 2 | ||

| Toxicity index | NES 713-1985 | — | 1 | |

| Halogen acid gas evolution | IEC 60754-1 | mg/g | 0 | |

Others

| Properties | Test Standards | Units | UV XLPE (Low smoke HFFR ) |

| Dielectric strength | IEC 60243 | kV/mm | 35 |

| Resistivity at(20℃) | IEC 60093 | Ω.m | 2.5×10 12 |

| Thermal Shock(150℃×1 h) | IEC 60811-3-1 | -- | Pass |

| Hear shrinkage(100℃×1 h) | IEC 60811-1-3 | % | 1.0 |

Extruder:

L/D ration: between 18:1~25:1 Screw compression: between 1.1~2.0 Single screw thread

Extrusion Recommendation

| Gate | Die | Neck | Zone 3 | Zone 2 | Feed |

| 145℃ | 145℃ | 140℃ | 135℃ | 120℃ | 100℃ |

Ultraviolet Radiation Cable Crosslinking Equipment: Normal UV radiation cable crosslinking equipment.

Extrusion Speed: Depends on different colors. Especially production rate of blue color reduces.

Comparison Table of production speed and thermal extension of UV cross-linked

low-smoke halogen-free flame retardant polyolefin cable material (For reference only)

| Conductor cross section ( mm² ) | Nominal thickness of insulation ( mm ) | Production speed ( m/min ) | Thermal extension ( % ) |

| 1.5 | 0.7 | 100~140 | 50~100 |

| 2.5 | 0.8 | 80~120 | 50~90 |

| 4.0 | 0.8 | 80~120 | 50~90 |

| 6.0 | 0.9 | 50~70 | 60~100 |

| 10.0 | 1.0 | 30~45 | 60~100 |

Remark: When red, yellow, blue and green master batches are used, the production speed will be reduced by about 10~15%.

Color master batches added quantity should not exceed 0.4%.

Indoor colored cables——XLPE Product

Indoor colored cables——XLPE Product

Indoor colored cables——XLPE Product

Indoor colored cables——XLPE Product

Dear customers, no need to worry about your products colors, POLYROCKS has professional colour matching department, providing free colour matching service. Any colour requirements, kindly please contact us by email: sales@polyrocks.com.

POLYROCKS focus on provide prompt pre/after-sales service, we have professional injection molding engineers and technical service engineers to provide accurate information and timely service. Any questions or needs, you are welcome to contact us by email: sales@polyrocks.com.

Any purchasing questions, welcome to contact our customer service, helps will be provided by them.

Copyright © POLYROCKS CHEMICAL CO., LTD. All Rights Reserved |

Sitemap

| Powered by

粤ICP备10040394号

粤ICP备10040394号

CONTACT US

QUICK ENQUIRE FORM

* Indicate Mandatory fields