Product description: Irradiation Cross-linked Halogen-free Flame Retardant Polyolefin

Main application: Electronic wires, automotive wires, etc.

Flammability rating: Passed VW-1

Temperature class: 105℃

Features: Excellent mechanical properties, electrical properties, flame retardant performance, and processing performance. Comply with UL1581, flame retardant through VW-1, used in high flame retardant cable field.

PS:We can provide you with free samples for evaluation and test, please feel free to contact us

EP8400X105VWB temperature resistance 105℃ ,with excellent Mechanical properties, electrical properties, flame retardant performance and processing performance. The flammability reach UL1581 VW-1, suitable for high flame retardant occasions.

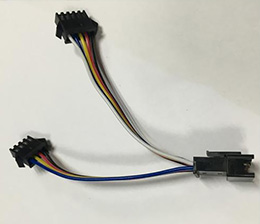

Wire & Cable

Application: Electronic wires, automotive wries, etc.

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

LSZH FRPE

Recommended Irradiation Dose: 8-10Mrad

Temperature: 105°C

Packing/Storage: 25kg/package; Transport as general chemicals. Keep it dry, in cool place and avoid direct sunlight.

| Properties | Test Standards | Units | Irradiation Cross-linked HFFR Polyolefin(VW-1) | |

| Density | ASTM D-792 | g/cm3 | 1.03±0.03 | |

| Tensile Strength | IEC 60811-1-1 | MPa | >11.0 | |

| Elongation | % | >200 | ||

| Tensile Strength After Irradiation | Cable standard | Mpa | >13.0 | |

| Elongation After Irradiation | % | >200 | ||

| Aging136℃×168h | Tensile strength retention | Cable standard | % | >90 |

| Elongation retention | % | >90 | ||

| Shore Hardness A | ASTM D 2240 | -- | 94±3 | |

| Shore Hardness D | ASTIM D 2240 | -- | 38±3 | |

| Brittle temperature | IEC60811-1-4 | ℃ | -25 | |

| Dielectric | IEC60243 | kV/mm | 25 | |

| Resistivity at(20℃) | IEC60167 | Ω·cm | >1.0×1012 | |

| Flammability | UL1581VW-1 | -- | PASS | |

Extrusion Recommendation

| Drying/Time | Gate | Die | Neck | Zone 3 | Zone 2 | Feed |

| 85℃(2 hours) | 185℃ | 182℃ | 182℃ | 172℃ | 170℃ | 140℃ |

Remark: The above laboratory test data are just for reference only; It's not a basis for quality assurance.

Electronic Wire——XLPE Product

Electronic Wire——XLPE Product

Automobile Wire——XLPE Product

Automobile Wire——XLPE Product

Dear customers, no need to worry about your products colors, POLYROCKS has professional colour matching department, providing free colour matching service. Any colour requirements, kindly please contact us by email: sales@polyrocks.com.

POLYROCKS focus on provide prompt pre/after-sales service, we have professional injection molding engineers and technical service engineers to provide accurate information and timely service. Any questions or needs, you are welcome to contact us by email: sales@polyrocks.com.

Any purchasing questions, welcome to contact our customer service, helps will be provided by them.

Copyright © POLYROCKS CHEMICAL CO., LTD. All Rights Reserved |

Sitemap

| Powered by

粤ICP备10040394号

粤ICP备10040394号

CONTACT US

QUICK ENQUIRE FORM

* Indicate Mandatory fields